| |

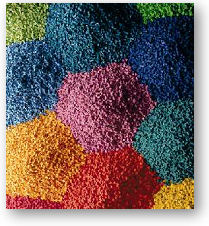

Quality Control

Great

quality starts with the highest standards in raw materials and total

control of processing. We follow through with strict ISO training and

internal audits. Great

quality starts with the highest standards in raw materials and total

control of processing. We follow through with strict ISO training and

internal audits.

Training

At NPC, the training of our production workers is the “keystone” to

our quality and precision production. Our Production Training Department

conducts a formal training program, with all new employees, that is

up to six weeks in length. Every six months all production workers are

evaluated

on their quality performance to determine if additional training is

needed. As a new product or process is introduced into our system, the

training

department develops a program to train all existing workers.

Production Standards

Our Processing Control System sets the variable that

control the quality of our product. The cleaning of a blender, blending

procedures,

blending time, extrusion temperatures, RPM, AMPS, classification methods,

and the line cleaning method are all documented and followed for each

individual color formula and individual customer’s requirements.

Calibration All measuring devices (i.e. Scales, temperature gauges etc.)

are calibrated on a regular ISO certified basis to ensure their

accuracy. This occurs, on average, every 90 days.

Quality Standards All customer requirements regarding shipping or material

content are available during the production process and are monitored

to ensure each production run meets your individual requirements.

Requirements regarding any shipping specifications are also monitored

and carried out. This includes packaging specifications, such as

plastic gaylords, barrels, bags or super sacks. It also includes

delivery schedule requirements, such as bookings, specified delivery

hours

and restricted

days.

| |